Грешка у формату е-поште

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Вести

Maintenance and Use of Die Casting Molds

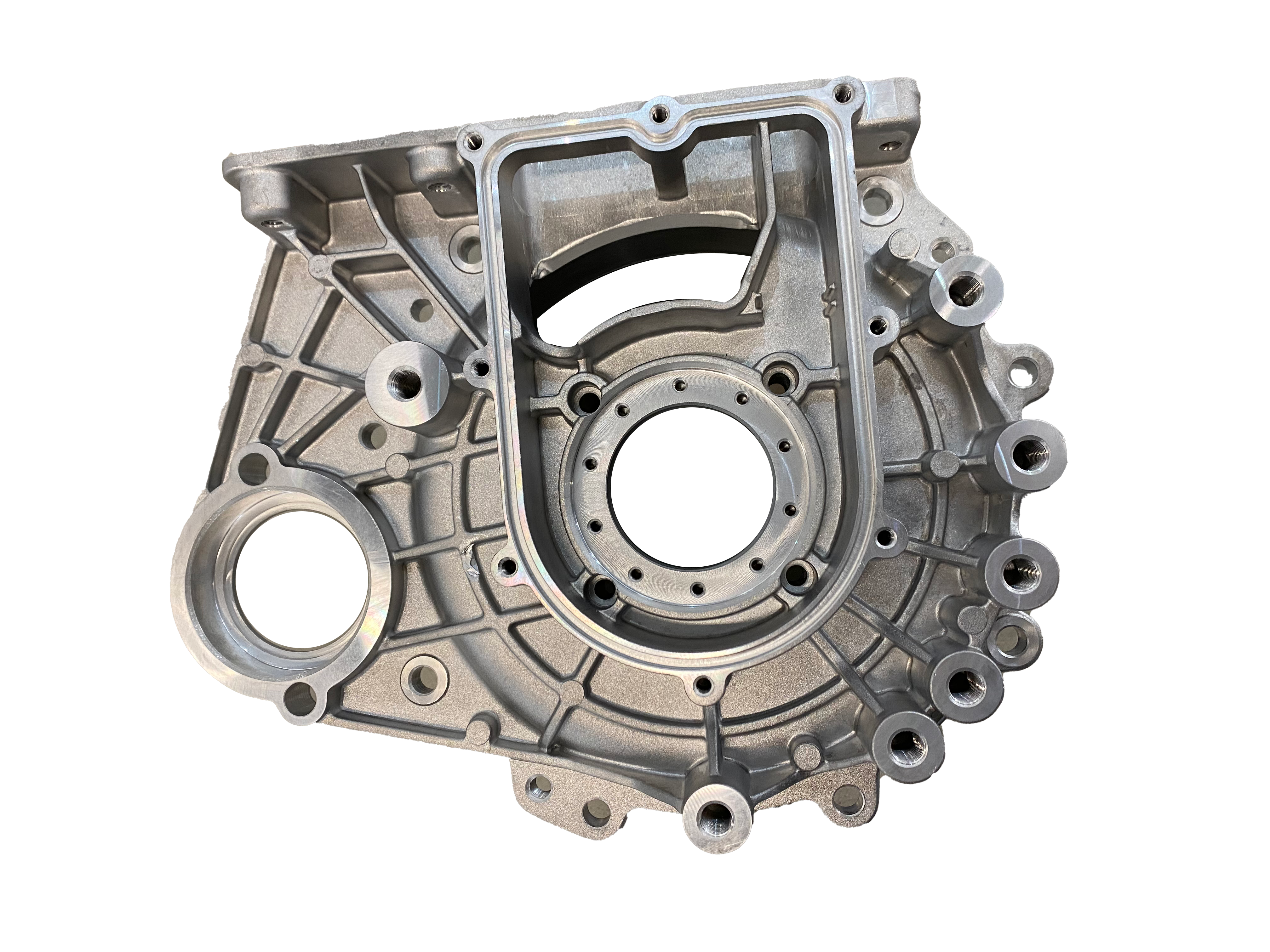

The injection mold is classified as a processing method for forging liquid die forging and a special-purpose die-casting die-forging machine. For aluminum die-casting, three factors are indispensable: aluminum die-casting material, aluminum die-casting machine, and abrasive tools. It is used in the whole process of application and production to develop the production output power, the quality of well-known brands, and its high economic benefits, and to allow the injection mold to obtain the application of broadening the life limit. The application and maintenance of the injection mold are very critical.

Proper application and maintenance methods of injection molds:

Minimize the rapid cooling and heating of the abrasive tool as much as possible, and continue production as much as possible. In the case of cold molds, high-speed injection is strictly prohibited.

During the whole process of aluminum die casting, the injection mold has always been in a reciprocating fatigue state of thermal expansion and contraction, and most of the temperature of the mold cavity has been changed back and forth between 160 degrees and 350 degrees. , followed by wear and tear of abrasives. When the production starts under the condition of cold mold, the temperature of the abrasive tool starts to increase from the ultra-low temperature, the temperature difference increases, the expansion of the abrasive tool decreases and increases, and the fatigue of the related abrasive tool increases relatively, which will accelerate the damage of the abrasive tool and reduce the life of the abrasive tool. Therefore, in the production of aluminum die-casting, it is necessary to continue the production as much as possible, reduce the rapid cooling and heating of the abrasive tool as much as possible, and then extend the life of the abrasive tool.

In addition, in the case of a cold mold, the mold does not reach the temperature of all normal production, and the gap between the molds is relatively large. Under such conditions, it is strictly forbidden to open the high-speed injection and increase. Otherwise, the gap positions of the abrasive tool, including the guide rail slider, the small chain hole, etc., are easily inserted into the aluminum skin, and then the abrasive tool is destroyed, which will endanger the life of the abrasive tool.

Reduce the injection rate as much as possible, reduce the specific pressure as much as possible, and reduce the impact of the abrasive tool.

In the production of aluminum die-casting, the height of the injection rate not only affects the filling rate of aluminum die-casting and the injection rate of the injection port, but also the high injection rate and the maximum impact value. Therefore, the injection rate is high, the speed of the injection port is faster, the erosion of the abrasive tool will be intensified, the maximum impact value will increase, the impact force received by the abrasive tool will also increase, and the life of the abrasive tool will be greatly reduced. Therefore, when we adjust the casting process, we should reduce the injection rate as much as possible while ensuring the quality of the product. It is very important to develop the life of the abrasive tool and the economic benefits of the aluminum die-casting company. At this stage, excellent aluminum die-casting machine weapons are equipped with injection brake pedal equipment, which is very beneficial to reducing the maximum value of impact, reducing the impact force received by abrasives, and developing abrasive tool life.

The injection specific pressure in the casting process is also a key main parameter, and the injection specific pressure is generally 400-900kg/cubic centimeter according to the quality regulations and characteristics of the castings. Over 900kg/cubic centimeter, the general effect on the internal quality of castings is not large. However, if the injection pressure is too high, not only does the expansion force accepted by the abrasive tool increase, but also the expansion force exceeds the clamping force of the CNC lathe, resulting in aluminum channeling. At the same time, if the expansion force of the abrasive tool is large, it will also damage the abrasive tool or reduce its life of the abrasive tool.

Therefore, in the production of aluminum die-casting, in addition to attaching great importance to the injection rate, we should also attach great importance to the injection specific pressure. Because the injection specific pressure is not as simple as the injection rate investigation, it is usually careless. In fact, the injection specific pressure is a key parameter in the casting process, which not only harms the quality of the casting, but also the life of the abrasive tool. This point should be highly valued by aluminum die-casting companies.

Conclusion

For more information about the hot chamber die casting method,rotor die casting process,die casting aluminium parts, we are glad to answer for you.